|

No.

|

Name

|

Power

(kw) |

Size

(mm) |

|

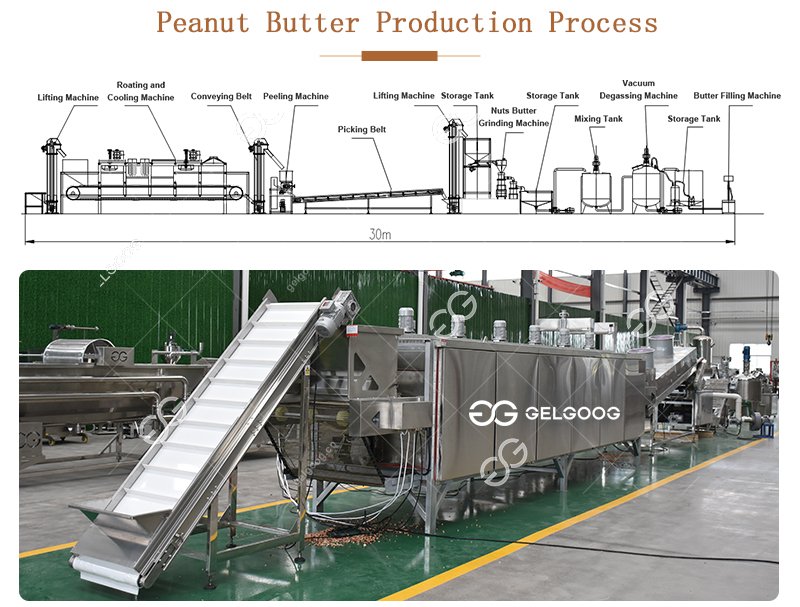

1

|

Feeder

|

0.55

|

700*700*800

|

|

2

|

Hoist

|

0.75

|

1000*500*2800

|

|

3

|

Continuous baking machine

|

70

|

5.8*1200*2600

|

|

4

|

Hoist

|

0.75

|

1000*500*3000

|

|

5

|

Continuous cooling machine

|

8

|

6000*800*2600

|

|

6

|

Peeling machine for half

|

1.5

|

1100*700*1300

|

|

7

|

Screening belt

|

0.75

|

5000*800*1000

|

|

8

|

Hoist

|

0.75

|

1000*500*3400

|

|

9

|

store material feeding machine

|

0.55

|

700*700*2200

|

|

10

|

Butter grinding machine

|

11*2 sets

|

1000*350*900

|

|

11

|

Storage tank

|

|

200L

|

|

12

|

Paste pump

|

1.5

|

1200*300*350

|

|

13

|

Mixing tank

|

2.2

|

300L

|

|

14

|

Vacuum degassing tank

|

2.2

|

300L

|

|

15

|

Paste pump

|

1.5

|

1200*300*350

|

E-Mailsales@gelgoog.com

E-Mailsales@gelgoog.com Contact0086-18539931566

Contact0086-18539931566 Whatsapp0086-18539931566

Whatsapp0086-18539931566