Peanut products not only have high nutritional value, but also have an appealing aroma, and are very popular with consumers at home and abroad. Among many peanut products, peanut butter is famous for its delicate taste, rich peanut flavor and good processing performance. Peanut butter has a wide range of uses. It can be directly used as a condiment for Chinese and Western food spreads, as a cooking condiment, and as a filling for cakes and small foods. The market demand is large. Here will introduce manufacting process of peanut butter in a factory.

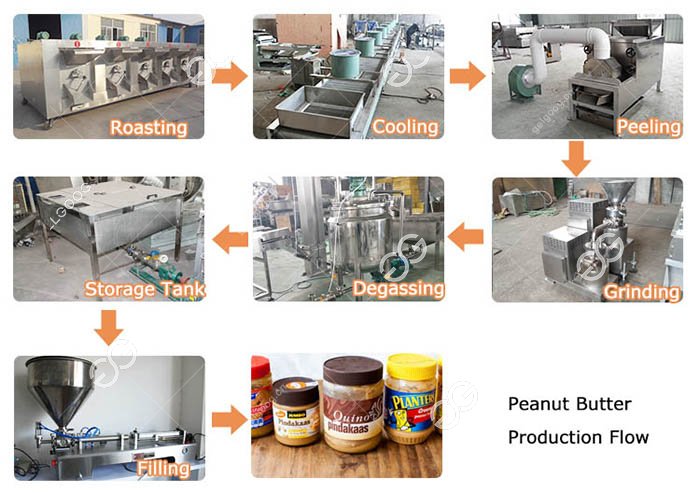

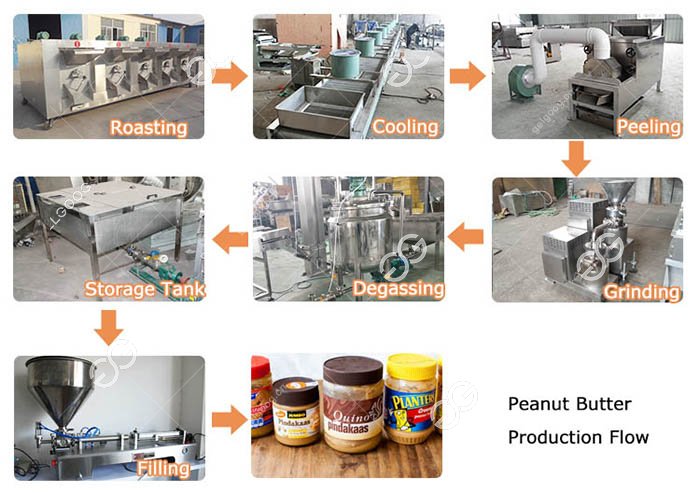

The processing flow of peanut butter: raw material selection → blanching → cooling → stripping → rinsing → beating → micro-grinding → deployment → homogenization → vacuum concentration and sterilization → canning → sterilization → cooling → finished product