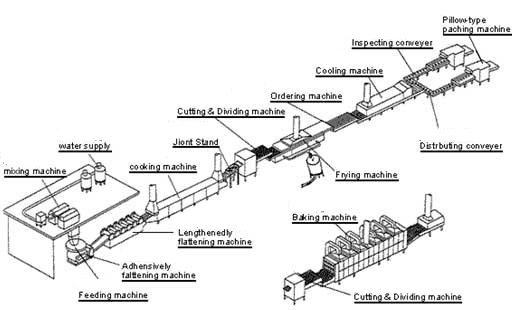

If i want to buy one production line, how much area of the plant?

For the instant noodle production line is quite large, needs big room, length more than 60 meter, width more than 10, height more than 8. As for other specific situation, we can chat online in detail.

What is the function of noodle rolling mahcine?

Press dough from 12mm into 1mm.

How long does it take to fry instant noodles in frying machine?

About 70-80 seconds.

In single layer noodle steaming machine, how long is enough?

About three minutes.

What if your voltage of your machine is not suitable for our country?

Don’t worry about it. We can change voltage to fit your country’s electric system.