- Carcass cleaning machine

-

- MOQ:1 /Sets

- Brand:GELGOOG

- Certification:CE

- Supply Ability:100 sets per month Set/Sets Per Month

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:6 Months

- LOADING PORT:Qingdao port

- Country Of Origin:China

- Features

- Technical Data

- FAQ

This hard(craker) and soft biscuit production line adoption standard, it can mix 500KGS flour every time. Blender is made up of two oars, controlled by adjusting-motor, at the same time users can choose low or high speed .It is a suit with mixing every type of dough blender and widely used to mix soft or hard biscuit's flour. To convenience mixing, the bucket stirrer can be demounted. The demounted bucket stirrer has wheels and can be move to pouring machine pour flour.

The main machine is biscuit forming machine and baking oven.

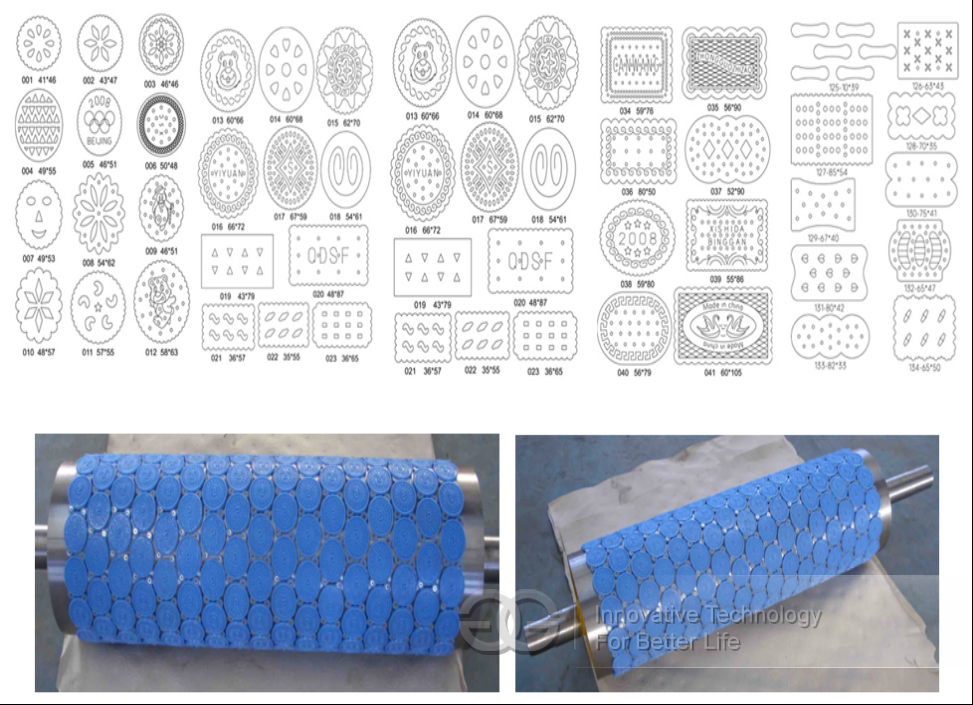

1. Rotary moulder forming machine is an important equipment of the production line and

adopts ministry standard

2. The machine combines roll-print and roll-cut

3. The mould is different from normal biscuit machine and dog biscuits making machine 4. It can be used as sole-roller or double roller.Configuration is consummate and ad-vanced.

5. It mainly used to produce hard biscuit.It has characteristic such as adj- usting thickness,noiseless,highinefficient.

6. It is a unearthliness equipment to pro- duce every types of high,middling & different tastes biscuit.

Final Products:

This biscuit production line may be Combined freely according to the condition of customers workshop space and requirement of biscuit technology. These all can reach the ideal purpose.

The line use imported electric components and its speeds are changed by frequency conversion.They save energy and are dependable,May be controlled single or combined.

Full Automatic line process from raw material mixing to final Packing

Flour Mixing---Moulding/Shaping--Baking---Oil Spraying---Cooling—Packing

Final Products:

cream biscuit, layer biscuit, soda cracker, calcium biscuit, multi-vitamin biscuit, vegetable biscuit, etc.

The oven is to make the formed biscuit into delicious food. You can choose different types of bakery oven (Electricity/gas/diesel/thermal oil) for baking different types of products. Dough rolling width is 250mm to 1200mm (if you have special needs, we can customize for you).

| No | name | quantity |

| 1 |

Dough Mixer |

2 set |

| 2 | Biscuit forming machine | 1set |

| 3 | transmission | 2set |

| 4 | Tunnel Electric Oven | 32m |

| 5 | biscuit oil spraying machine | 1set |

| 6 | 180 degree wheel | 1 |

| 7 | cooling machine | 10m |

| 8 | Biscuit Stacking Machine | 1 |

| 9 | Biscuit packaging table | |

| 10 | Control board | 1set |

| 11 | Biscuit sandwich machine | |

| 12 | 320 Packing machine | 1set |

1.Q:can I get some samples?and what is the delivery time?

A:we are honored to sent you samples for quality check.for delivery time,10-20 days after confirm the sample order.

2.Q:do you have the products in stock?

A:Yes,we have some model products can supply to you.

3.Q:can I mix different modles in one container?

A:yes,different modles can be mixed in one container,but the quantity of each model should not be less than MOQ.

4.Q:how does your factory do regarding quality control?

A:Quality is priority,we always attach great importance to quality control from the very beginning to the end of the production,every product will be fully assembled and carefully tested before it's packed for shipment.

5.Q:what's is your warranty terms?

A:we offer different warranty terms for different products,please contact with us for detailed warranty terms.

Follow us