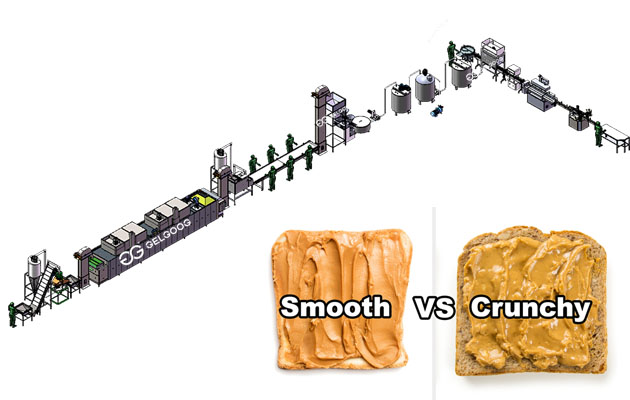

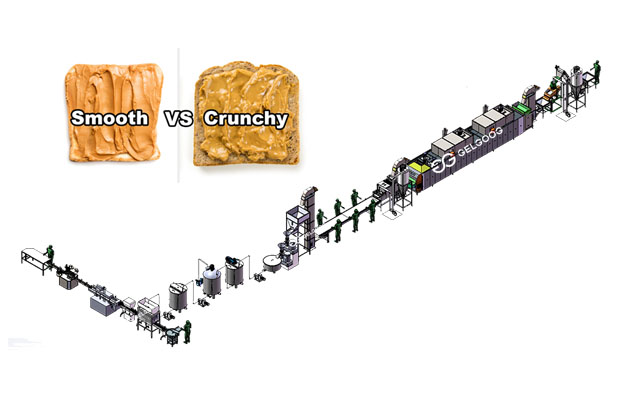

- Large Scale Smooth Peanut Butter Production Line 500 kg/h

-

- Brand:GELGOOG

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:12 Months

- Country Of Origin:China

- Features

- Technical Data

- FAQ

Large Scale Peanut Butter Production Line

This plant can process high-quality stable peanut butter, crunchy peanut butter and ordinary peanut butter in large scale production. At the same time, this plant can produce stable and normal tahini by change some parts.

This plant can process high-quality stable peanut butter, crunchy peanut butter and ordinary peanut butter in large scale production. At the same time, this plant can produce stable and normal tahini by change some parts.

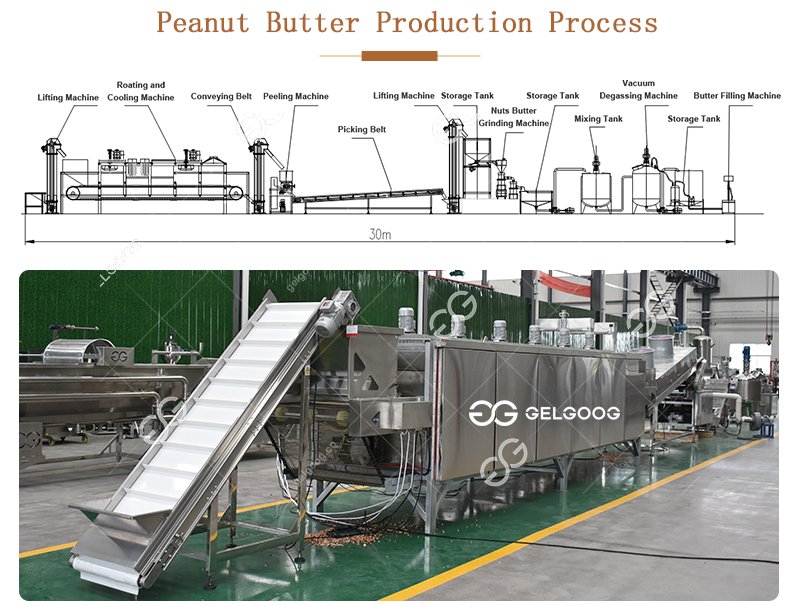

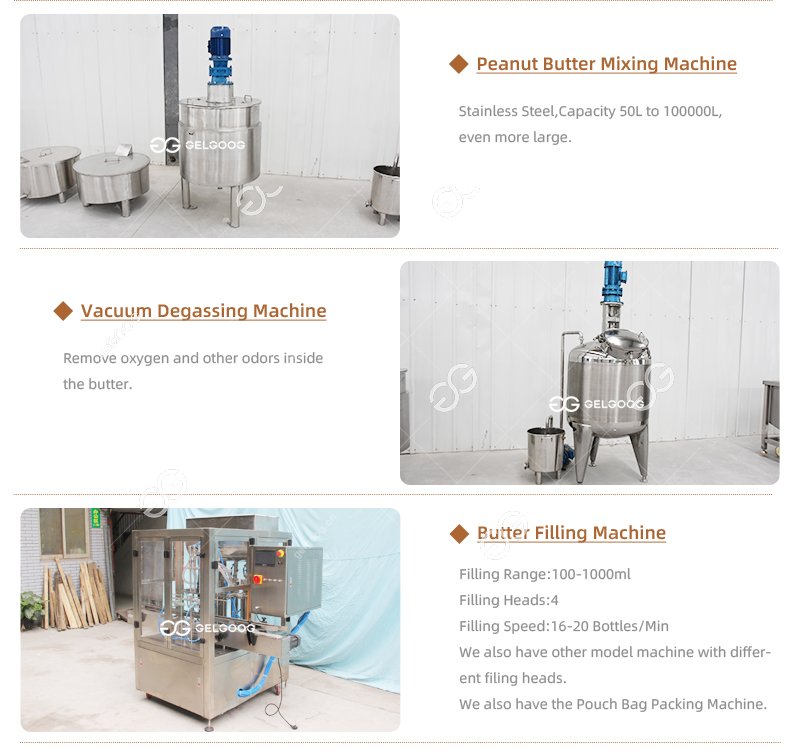

This peanut butter processing plant includes peanut roasting machine, roasted peanuts peeling machine, picking belt, lifting machine, peanut butter coarse grinding, mixing tank, mixer, homogenizer, peanut butter fine grinding machine, vacuum tank, cooling machine, filling machine, etc. This production line is characterized by flow operation, high mechanization degree, good reliability, all closed production, no pollution, is ideal equipment for stable peanut butter production.

Peanut Butter Manufacuting Process Description:

- Raw material acceptance: Each batch of peanuts will undergo sensory inspection after entering the factory, followed by moisture and impurity inspections, and use them only after they pass the inspection.

- Roasting: Put the qualified peanut kernels into the peanut roasting machine for roasting, the set temperature is about 180-185℃, and the time is about 20-25min. The roasted peanuts have uniform color and no scorching.

- Cooling: The roasted peanuts are placed in a stainless steel cooling box for cooling.

- Peeling and screening: the cooled peanuts are put into the peeling machine for peeling.

- Color sorter: Peanuts are sorted by color sorter after peeling.

- Manual picking: The peanuts that have been color sorted are then manually sorted to remove foreign bodies, insect-eaten grains, mildew grains, burnt paste grains, impurities, etc.

- Metal detection: The selected peanuts go through the gold probe to the next process.

- Preparation of grinding sauce: Put the selected peanuts into the grinding sauce pot for grinding, conduct the first salt grinding and coarse grinding, and grind it to a medium fineness of 100 mesh, then add stabilizers and related auxiliary materials, in the mixing tank, Heat the peanut butter to 100-110℃, mix well and sterilize at high temperature. Carry out the second sugar grinding and fine grinding, and grind it into a fine and smooth finished product with 200 meshes.

- Metal detection: The peanut butter products that have been cooled are tested every 2 hours. 10. Filling: Pack the finished peanut butter in the package specified by the customer, and pack it in quantitative quantity.

- Stability: The packed finished peanut butter is transferred to the stable room, and after the product reaches the best stable state, it can be packed.

- Packaging: The products that have passed the inspection will be marked and packaged and put into storage.

- Finished product inspection: Each batch of products should be inspected before leaving the factory. Only after passing the inspection and attaching the certificate can they leave the factory.

This industrial peanut butter production line can be customized according to the market demand, the core equipment of the complete production line - coarse grinding machines and fine grinding machines have been improved and optimized in a number of ways, and the processing fineness has been further improved. The complete peanut butter production line is highly mechanized, reliable and fully closed. It has the characteristics of simple operation, smooth operation, low noise, easy maintenance, corrosion resistance, wide use and wide variety.

|

No.

|

Name

|

Power

(kw) |

Size(mm)

|

|

1

|

Hoist

|

0.75

|

1500*800*3000

|

|

2

|

Baking and cooling machine

|

130

|

8000*1900*2600

|

|

3

|

Hoist

|

0.75

|

1000*500*2800

|

|

4

|

Peeling machine for half

|

1.5

|

1100*900*1100

|

|

5

|

Screening belt

|

0.75

|

6000*800*1000

|

|

6

|

Hoist

|

0.75

|

1000*500*3400

|

|

7

|

store material feeding machine

|

0.55

|

700*700*2200

|

|

8

|

Butter grinding machine

|

11*2

|

900*350*900

|

|

9

|

Storage tank

|

|

500L

|

|

10

|

Paste pump

|

1.5

|

1200*300*350

|

|

11

|

Mixing tank

|

4

|

1000L

|

|

12

|

Vacuum degassing tank

|

4

|

1000L

|

|

13

|

Paste pump

|

1.5

|

1200*300*350

|

|

14

|

Storage tank

|

|

1000L

|

|

15

|

Filling machine

|

1.5

|

1000*1100*1700

|

|

16

|

Control cabinet

|

|

|

|

17

|

Pipeline

|

|

|

1. Do you have manual or video for peanut butter production line operation?

Yes, we can send you production line video, you can just leave your email or mobile number here.

2. I want to make 200 kilograms peanut butter per hour, can you suggest suitable model?

Of course, you can tell us the process flow you want to produce peanut butter, our engineer will give you suitable peanut butter processing project.

Of course, you can tell us the process flow you want to produce peanut butter, our engineer will give you suitable peanut butter processing project.

3. How much is the peanut butter production line?

Some factors depends on the price, production capacity and processing technology. we make the price according to our comprehensive costing. And our price will be competitive becasue we consider of material cost, labor force, exchange fluctuations rade, economic situation etc.

4.Can you customize the voltage for me?

Sure, just tell us the specific requirement, we can customize for you.

Follow us