- Gelgoog Instant Noodle Manufacturing Plant 100000 Bags/8h

-

- Brand:GELGOOG

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:12 Months

- Country Of Origin:China

- Features

- Technical Data

- FAQ

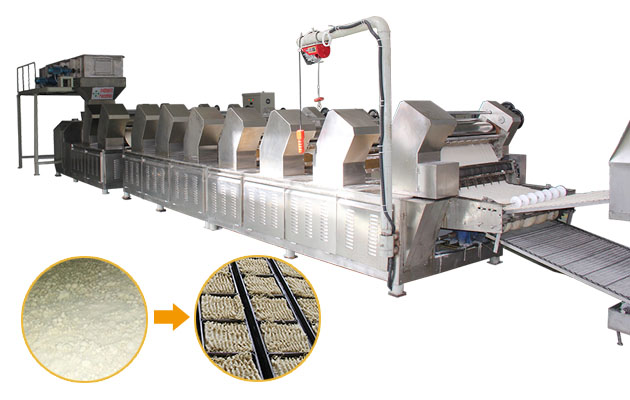

Automatic Instant Noodles Manufacturing Plant Introduction

The instant noodle full plant is divided into fried and non-fried instant noodle production line. The process of fried instant noodle production line includes salt water mixing and metering system, noodle mixing, maturation, noodle pressing, steaming noodle, frying, finishing, air cooling, conveying, and packaging. The shapes of the noodles that can be made are square and round, and the weight is determined by the customer's choice.

The whole set of equipment adopts automated assembly line production, such as automatic cutting of noodles, automatic folding, and automatic feeding into the frying box. The output ranges from 60,000 to 200,000 bags in 8 hours.

So far, our company has exported to more than 20 countries, involving Europe, Southeast Asia, Africa, South America, the Middle East and other regions.

Instant Noodle Manufacturing Process

- Flour Mixing: Mixing flour and water evenly for a certain period of time to form a wet dough with certain processing properties

- Dough Curing: It is a process to further improve the processing performance of the dough with the passage of time

- Compound rolling: The matured dough is pressed into two dough sheets through two parallel pressure rollers, and pressed into a uniform and firm dough sheet.

- Cutting and forming: The dough sheet passes through a pair of knife rollers at high speed, is cut into strips, and is transferred to the forming mesh belt through the former

- Steaming: Heating and steaming noodles through steam at a certain time and temperature

- Frying: Put the quantitatively cut noodles into the frying box, pass the high-temperature oil tank, the water in the noodles quickly vaporize, the noodles form a porous structure, and the starch is further gelatinized

- Air cooling: The temperature of the noodles just out of the fryer is too high, which will burn the packaging film and the soup, so several sets of fans are often used to cool them to room temperature for packaging

- Cooling: Forced cooling to room temperature or slightly higher than room temperature by blowing air in the cooler,

- Packaging: Complete the packaging with composite plastic film or polystyrene foam that meets hygienic requirements.

| Model | Capacity | Power | Floor Area | Noodle Weight |

| BFP-6Y | 60000bags /8h | 55kw | 46*5*5 m | 65g |

| BFP-8Y | 80,000 bags/8h | 60kw | 50*5*5 m | 60g |

| BFP-10Y | 100,000 bags/8h | 85kw | 55*5*5 m | 60g |

| BFP-16Y | 160,000 bags/8h | 105kw | 65*5*5 m | 65g |

| BFP-20Y | 200,000 bags/8h | 160kw | 72*5*5 m | 60g |

Follow us