- Industrial Sugar Cone Baking Machine for Sale GGDCL-37

-

- Brand:GELGOOG

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:12 Months

- Country Of Origin:China

- Features

- Technical Data

- FAQ

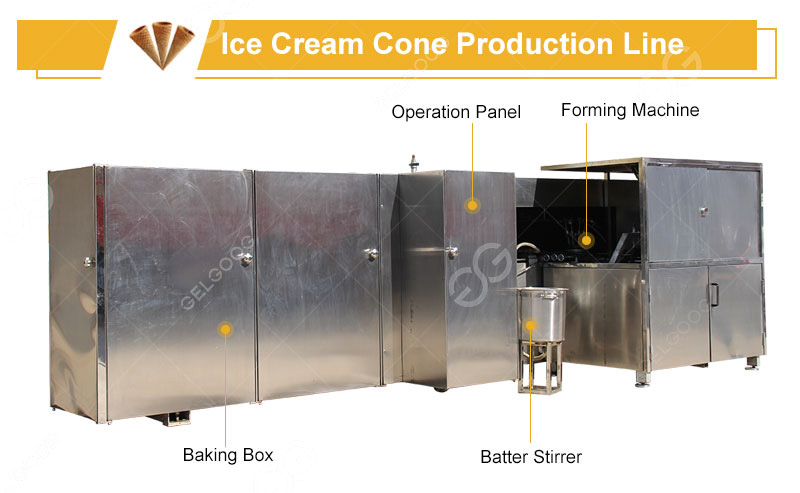

Introduction of Automatic Ice Cream Sugar Cone Production Line

The GGDCL-37 automatic sugar cone baking machine is the most ideal processing equipment for the rolled sugar cones. The produced cones are of uniform color, bright color, crispy and delicious, clean and hygienic.

This machine is used to inject the batter into the baking sheet, and it will be cooked into ice cream cone sheet shape, and the automatic mold will automatically move into a cone-shaped crispy egg cone by a rolling part. The cone made by this machine is crisp and refreshing.

Advantages of Automatic Ice Cream Cone Baking Machine

1. High automation: The oven uses gas for heating, and the equipment adopts sizing, baking, wrapping and forming, demoulding, conveying finished products, and stacking counting. The output can reach 3000-3500 pieces/hour;

2. Product diversification: According to different molds, this equipment can produce various specifications of egg cones (flat-mouthed cones, natural side cones, egg rolls, bowl-shaped cups), etc.;

3. Novel structural design: the equipment parts are purchased from high-quality steel and installed on a solid steel structure. The door body adopts a double-layered door. The inner cover is made of galvanized sheet material with high-quality insulation cotton inside. Air thermal insulation and convection thermal insulation can reduce the temperature of the production site and achieve energy-saving effects;

4. The operating speed can be adjusted: the equipment has been debugged and started to run continuously, automatically and rotatingly, and the operating speed can be adjusted according to requirements;

5. Long mold life: The baking tray is made of high-quality ductile iron, which is durable and wear-resistant.

6. The combustion system is more advanced: using gas (natural gas or liquefied gas) heating, the burner will automatically ignite after the ignition button is activated, and the special design of the burner can maximize the use of energy, and the fire power can be adjusted according to the needs;

7. The control panel is easy to operate: the baking equipment is changed to adopt an easy-to-control button operating system or a modern PLC control system can be customized according to requirements for production setting, adjustment and control;

8. High safety system: This equipment can be equipped with advanced gas leak detection and alarm devices to better improve the production safety factor;

Working Video of Ice Cream Sugar Cones Production Process

| Model | DCL-37 | DCL-45 | DCL-55 |

| Drive motor | 1.5KW, 380V, 50 Hz | 2.2kw, 380,50Hz | 3KW, 380V 50Hz |

| Gas Consumption | 160 cube/24h | 200 cube/24h | 200cube/24h |

| Producing Capacity | 3000-3500 pcs/h | 3500-4000pcs/h | 4500-5000pcs/h |

| Machine Measurement | 7000*1800*1750mm | 8000*1850*1750mm | 9000*1900*1850mm |

| Total Weight | 4200kg | 4700kg | 5100kg |

Follow us